usecookie learnmore_usecookie

Atsižvelgiant į konkrečius jūsų pervežimo poreikius, Kässbohrer išverčiamos silo cisternos puspriekabės gali būti nuo 40 m3 iki 90 m3 tūrio.

Kässbohrer yra vienintelė puspriekabių gamintoja, galinti pagaminti vientisą silo cisterną, turinčią aliumininę važiuoklę ir iki 90m3 galintį siekti tūrį.

Išverčiamos silo cisterninės puspriekabės tinka miltelių arba granulių pavidalo medžiagoms, pavyzdžiui, pelenams, anglims, smėliui ir pan., pervežti. Kässbohrer išverčiamų silo cisternų serija K.SSK turi ypatingą ir patogią naudoti iškrovimo sistemą, leidžiančią sklandžiai išpilti medžiagas.

Vientisa ir besiūlė aukštos kokybės ir patvari važiuoklė – ilgos ir patikimos eksploatacijos garantija. Kässbohrer silo cisternos sukurtos sklandžiam medžiagos srautui be sustojimų. Priekabose sumontuotas 4 kW galios elektros siurblys, leidžiantis išversti medžiagas be traktoriaus pagalbos. Išvertimo sistema turi 5 etapų hidraulinę sistemą.

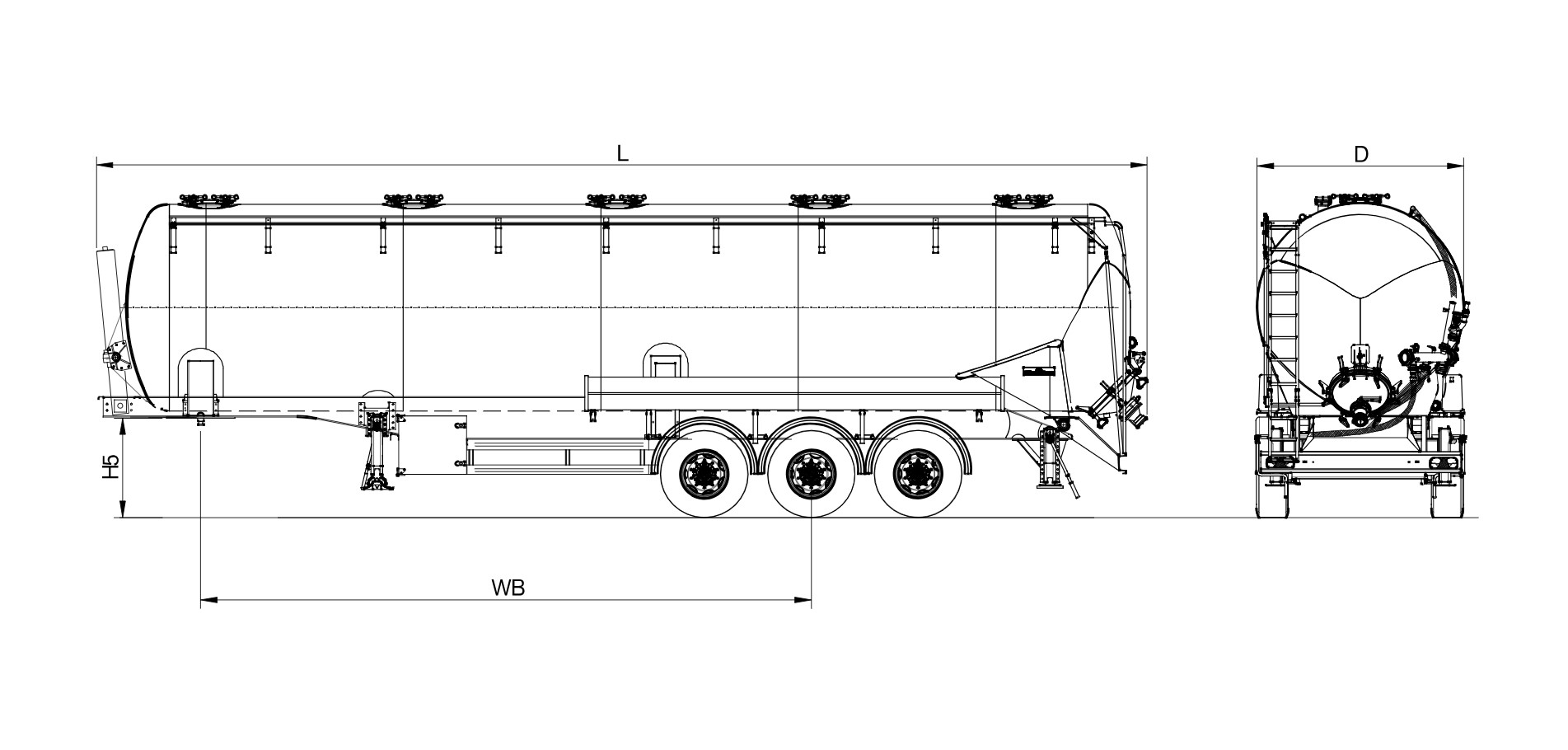

| TECHNICAL DATA | |

Fifth Wheel Height (H5) |

1.220 mm |

Tank Diameter (D) |

2.530 mm |

Wheelbase (WB) |

7.480 mm |

External Length (L) |

12.875 mm |

Volume |

60,0 m3 |

Tare Weight ±%3 |

6.150 kg |

Operation Temperature °C |

-20/80°C |

Test Pressure (Bar) |

3,0 bar |

Operation Pressure (Bar) |

2,0 bar |

| TECHNICAL INFORMATION | |

Chassis |

Extruded double T-type (double T type) profiles which are made of aluminum alloy, provides high quality and strength in accordance to ISO 1726 |

Brake System |

There is a dual-circuit electro-pneumatic braking system with EBS 2S/2M anti-blocking system suitable for UN ECE R13 regulation an d an integrated RSS electronic stability control system in the braking system |

Tyre Size |

385 / 65 R 22,5'' |

Axles |

BPW axles, 3 x 9 tons capacity with air suspensions and disc brakes |

Electric System |

ASPÖCK lighting system |

Body Type |

Aluminium cylindrical tank with DN700 discharging cone at the rear side |

Manhole Number |

5 x DN450 Pressure Type Domes |

Discharge Cone Dimension |

At the rear side of the tank, a stainless steel electro-polished discharge cone which has a diameter of DN 700 to DN 200 mm is mounted |

Hose Carrier |

2 x DN200, 5 m plastic hose holders with lockable rear cover are equipped in order to hold the hoses which are used to discharge the materials inside the tank |

| TECHNICAL CAPACITIES | |

Axle Load |

27.000 kg |

King Pin Capacity |

12.000 kg |

Gross Weight |

39.000 kg |

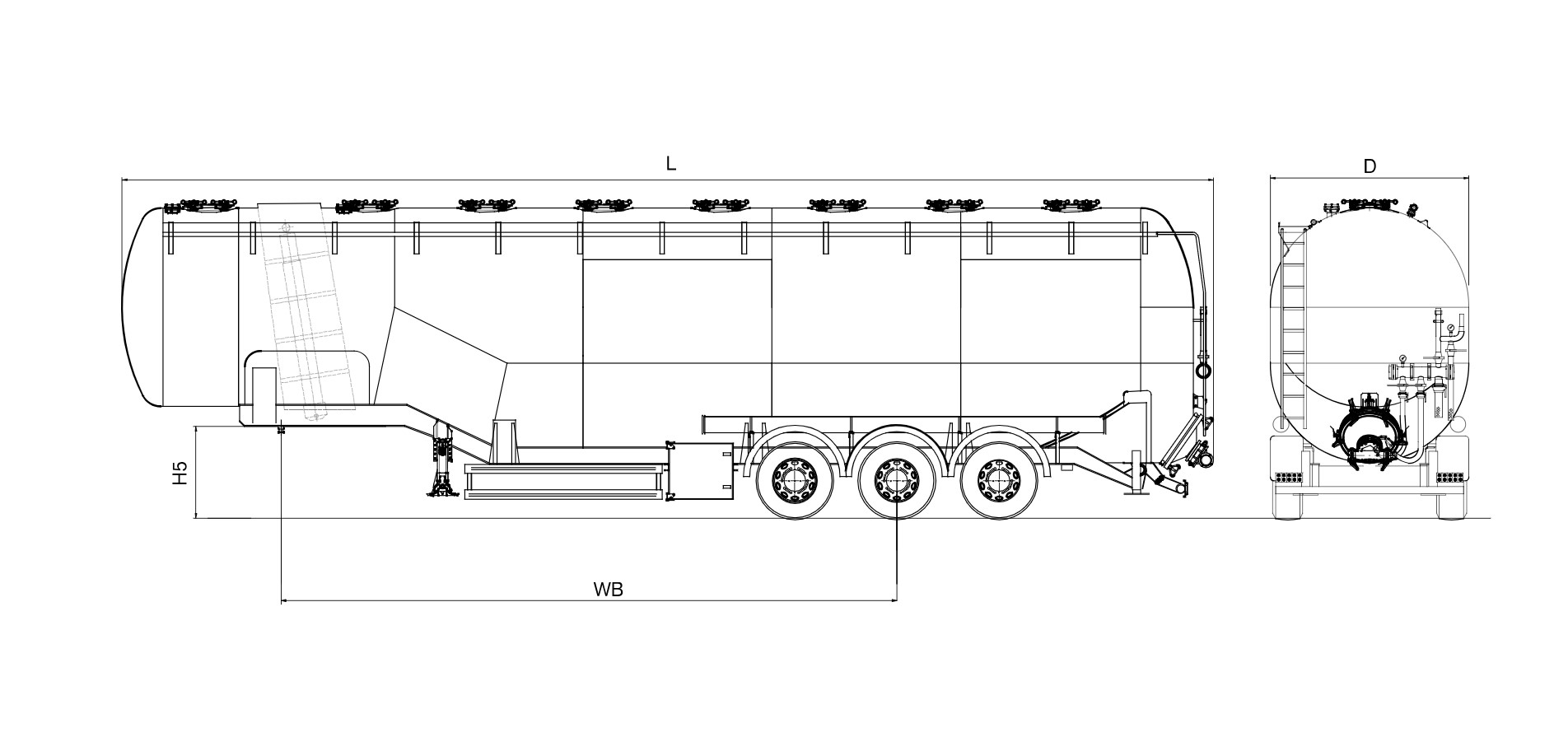

| TECHNICAL DATA | |

Fifth Wheel Height (H5) |

1.180 mm |

Tank Diameter (D) |

2.550 mm |

Wheelbase (WB) |

7.900 mm |

External Length (L) |

14.000 mm |

Volume |

90,0 m3 |

Tare Weight ±%3 |

8.700 kg |

Operation Temperature °C |

-20/80°C |

Test Pressure (Bar) |

3,0 bar |

Operation Pressure (Bar) |

2,0 bar |

| TECHNICAL INFORMATION | |

Chassis |

Two welded longitudinal I-beams with cross beams at necessary distances. Chassis beams and cross section are made of steel which provides high quality and strength in accordance to ISO 1726 |

Brake System |

There is a dual-circuit electro-pneumatic braking system with EBS 2S/2M anti-blocking system suitable for UN ECE R13 regulation an d an integrated RSS electronic stability control system in the braking system |

Tyre Size |

385 / 55 R 22,5'' |

Axles |

BPW axles, 3 x 9 tons capacity with air suspensions and disc brakes |

Electric System |

ASPÖCK lighting system |

Body Type |

Aluminium cylindrical tank with DN700 discharging cone at the rear side |

Manhole Number |

8 x DN450 Pressure Type Domes |

Discharge Cone Dimension |

At the rear side of the tank, a stainless steel electro-polished discharge cone which has a diameter of DN 700 to DN 200 mm is mounted |

Hose Carrier |

1 x DN200, 5 m plastic hose holder with lockable rear cover is equipped in order to hold the hose which is used to discharge the materials inside the tank |

| TECHNICAL CAPACITIES | |

Axle Load |

27.000 kg |

King Pin Capacity |

12.000 kg |

Gross Weight |

39.000 kg |

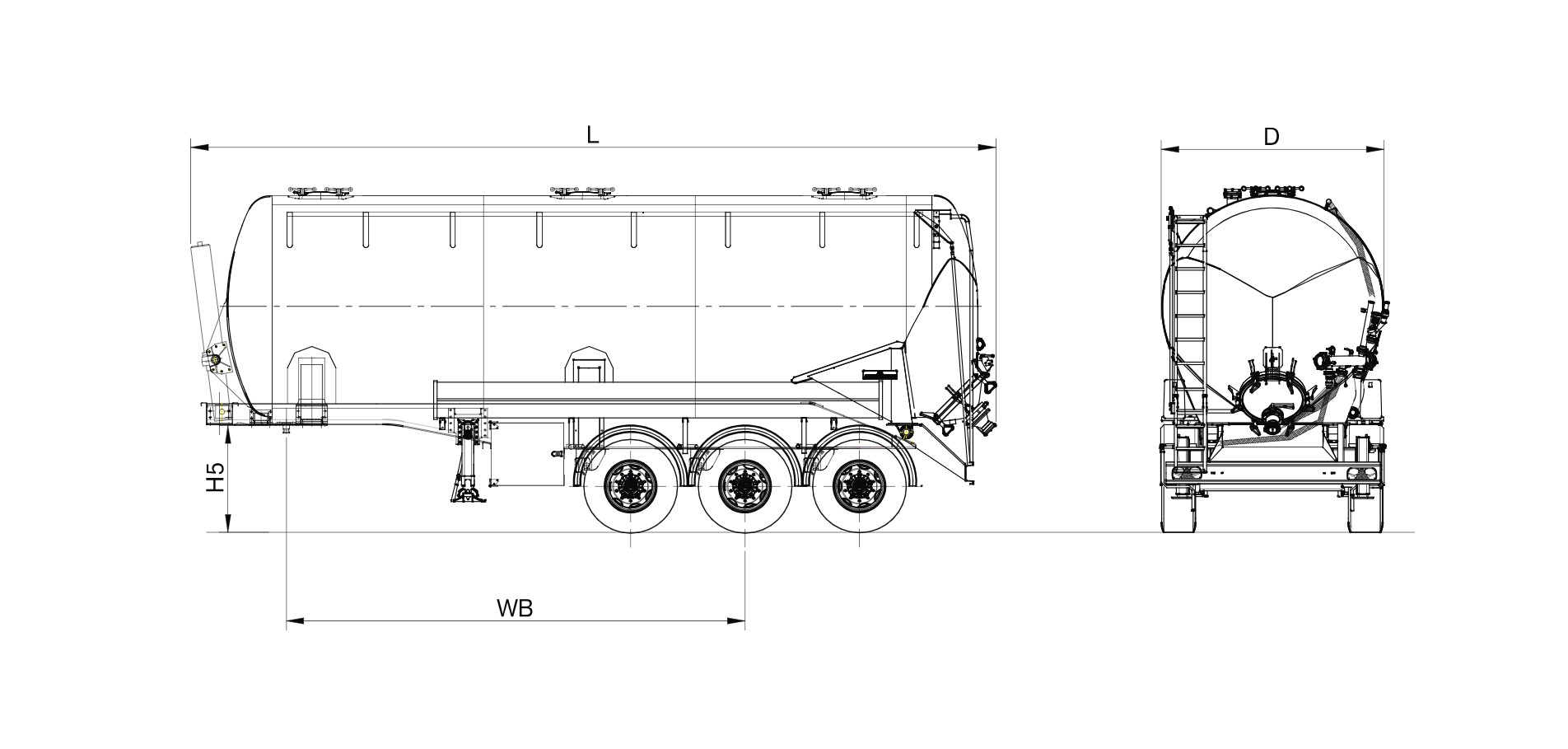

| TECHNICAL DATA | |

Fifth Wheel Height (H5) |

1.220 mm |

Tank Diameter (D) |

2.530 mm |

Wheelbase (WB) |

5.250 mm |

External Length (L) |

9.260 mm |

Volume |

40,0 m3 |

Tare Weight ±%3 |

5.150 kg |

Operation Temperature °C |

-20/80°C |

Test Pressure (Bar) |

3,0 bar |

Operation Pressure (Bar) |

2,0 bar |

| TECHNICAL INFORMATION | |

Chassis |

Extruded double T-type (double T type) profiles which are made of aluminum alloy, provides high quality and strength in accordance to ISO 1726 |

Brake System |

There is a dual-circuit electro-pneumatic braking system with EBS 2S/2M anti-blocking system suitable for UN ECE R13 regulation an d an integrated RSS electronic stability control system in the braking system |

Tyre Size |

385 / 65 R 22,5'' |

Axles |

BPW axles, 3 x 9 tons capacity with air suspensions and disc brakes |

Electric System |

ASPÖCK lighting system |

Body Type |

Aluminium cylindrical tank with DN700 discharging cone at the rear side |

Manhole Number |

3 x DN450 Pressure Type Domes |

Discharge Cone Dimension |

At the rear side of the tank, a stainless steel electro-polished discharge cone which has a diameter of DN 700 to DN 200 mm is mounted |

Hose Carrier |

2 x DN200, 5 m plastic hose holders with lockable rear cover are equipped in order to hold the hoses which are used to discharge the materials inside the tank |

| TECHNICAL CAPACITIES | |

Axle Load |

27.000 kg |

King Pin Capacity |

12.000 kg |

Gross Weight |

39.000 kg |